- Product introduction

main feature:

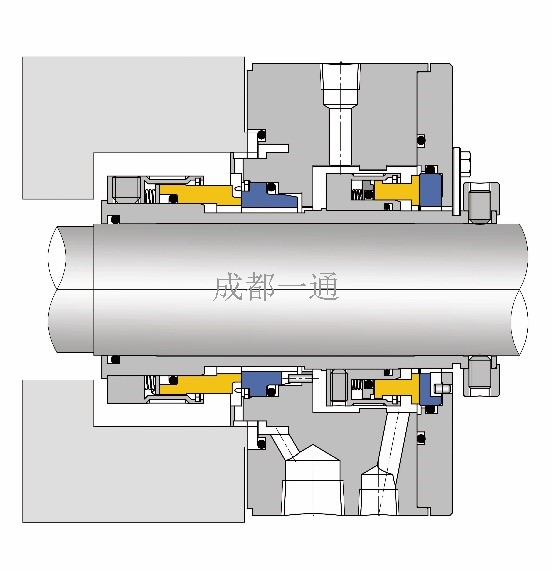

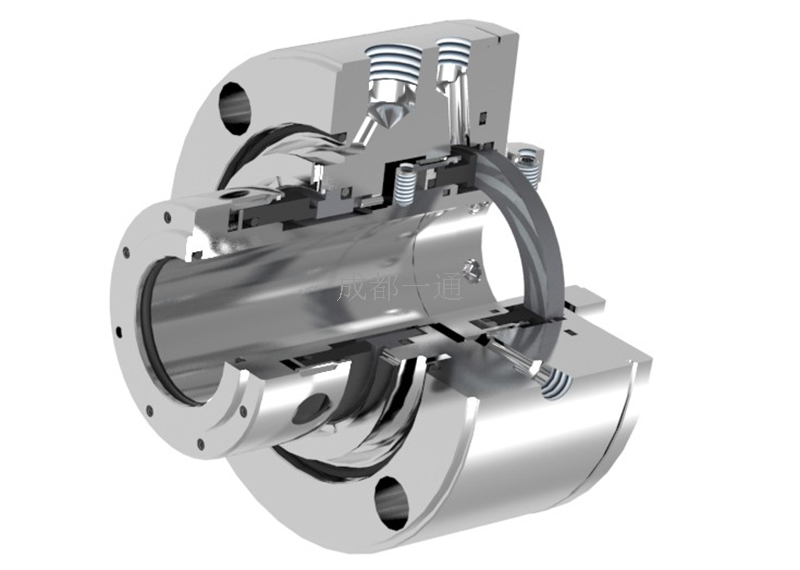

The primary seal adopts a contact mechanical seal, and the secondary seal adopts a non-contact dry gas seal. The primary sealed working medium is the medium itself, and the secondary sealed working medium is an external buffer gas.

Under normal circumstances, the primary seal bears the full pressure of the medium, and the secondary seal runs under low pressure or normal pressure. When the primary seal fails completely, the secondary seal functions as the main seal, and it can run safely for at least 8 hours.

The secondary seal is injected with buffer gas under pressure, and is isolated by comb seals to prevent the primary leaking medium from contaminating the secondary dry gas seal. The process medium leaked from the primary seal is taken to the torch combustion / collection tank for centralized discharge, safe and environmentally friendly ; The buffer gas under pressure can reduce the vaporization of the medium on the primary seal face, improve the lubrication effect of the mechanical seal, and extend the seal service life.

Sealed non-contact operation, energy saving, safety and environmental protection, reliable performance, simple operation, maintenance-free, and average service life of up to 3 years.

Using parameters:

Pressure: 0 ~ 10MPa

Temperature: -104 ~ 260 ℃

Speed: ≤3600r / min

Applicable working conditions:

It is suitable for various fluid media, and is mainly used for toxic and hazardous, flammable and explosive dangerous fluid media. Such as ethylene, propylene, liquefied gas, ammonia, MTBE, butadiene, aromatics, benzene media, etc.